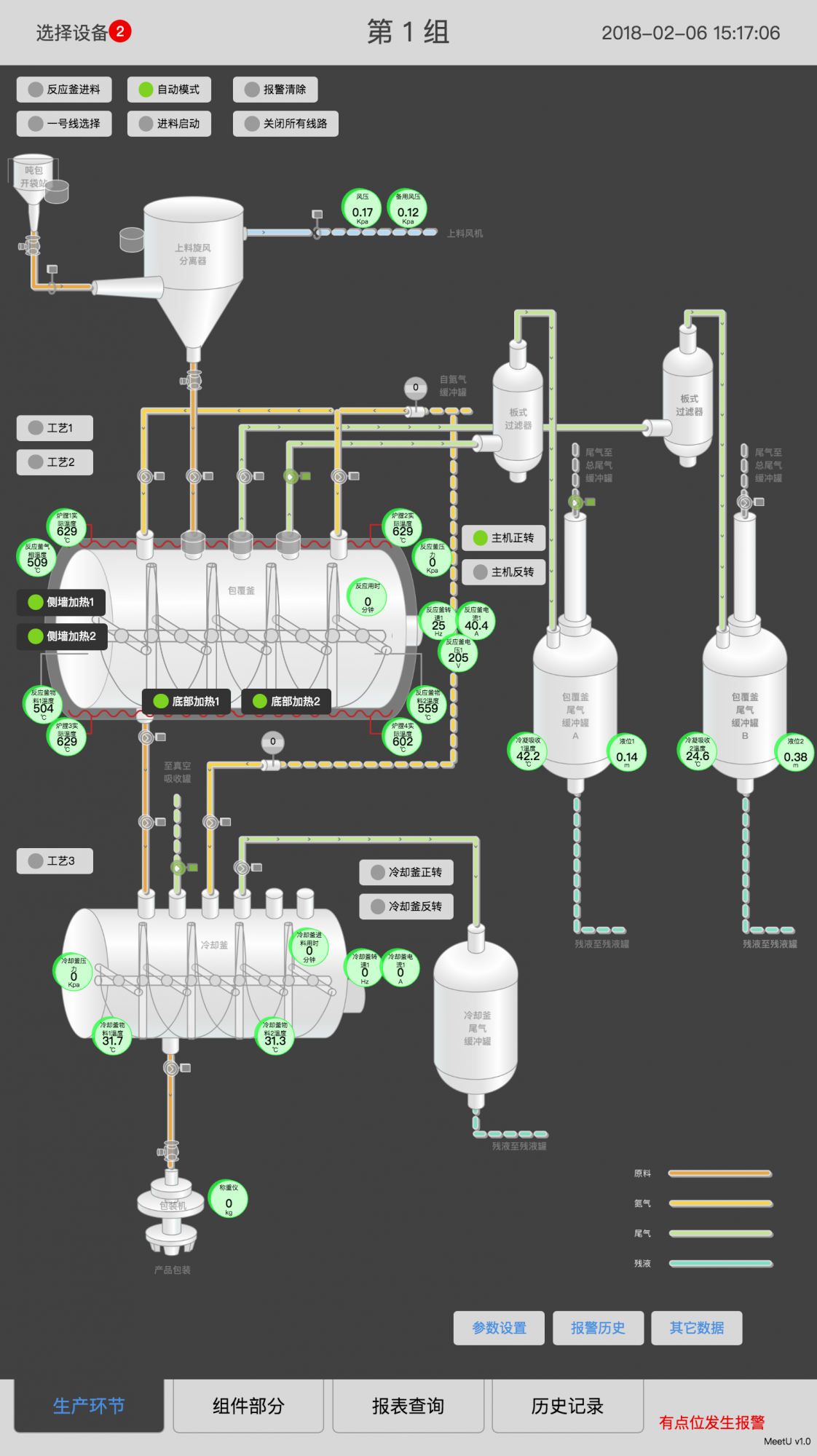

We set up an automation system with user interface for the newly established lithium battery factory of Ningbo Shanshan Group, which can intelligently monitor the conditions of each instrument and valve in the entire production line. Remote operation also helps maintenance personnel switch valves through this system.

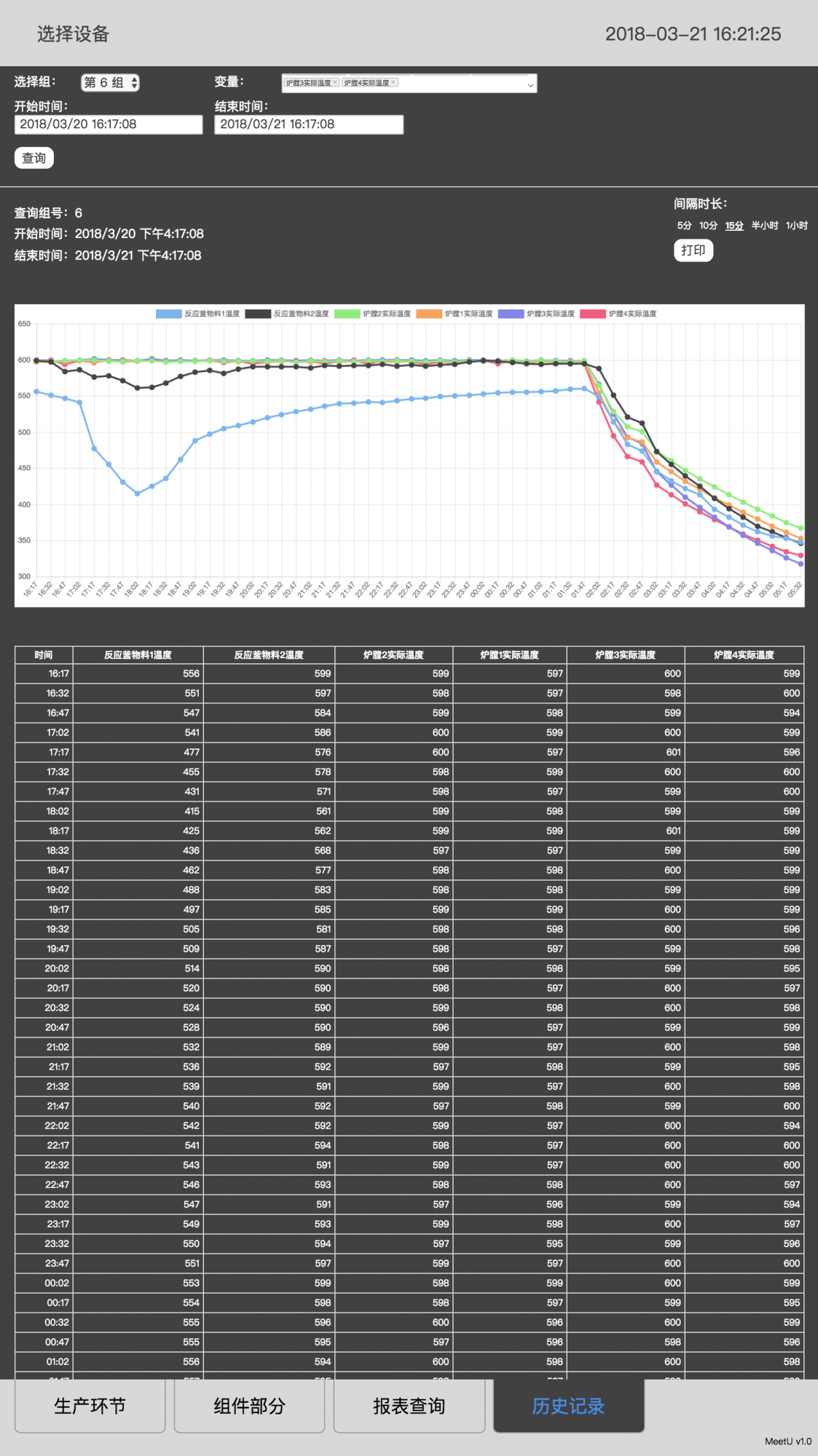

This industrial intelligent system speed up the responses to maintenance events in the production line through timely alarms and data analysis. Through remote operation, the time spent by workers onsite is reduced, and production safety is improved.

Wireless communication module is attached in all the data acquisition devices of this system, data transmission is strictly encrypted to ensure the security of the data. The operation and data viewing system can be accessed through the local area network without network environment or the wireless external network, provides convenience for stuff members in different locations.

In addition, the software generates long-term, accurate and visualized data report, which is the first-hand material for researching production status, increasing production efficiency, and ensuring safety in the factory.